Manufacturing and integrating a wide range of materials handling systems and equipment in-house brings control and benefits to systems integrators. David Priestman spoke with Bas van der Velden, Director of Intralogistics for Bowe Group, about how one intralogistics company achieves this.

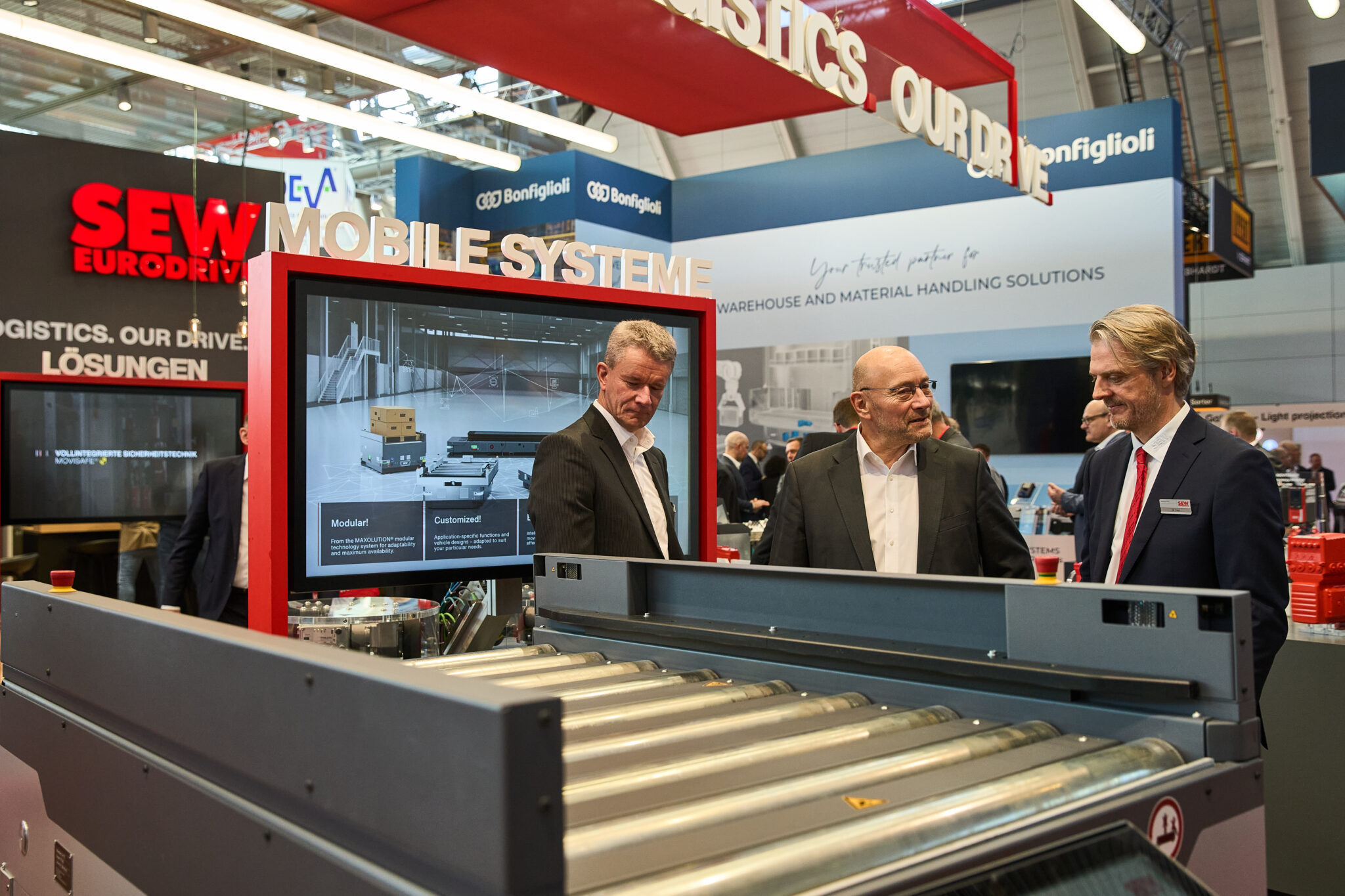

Logistics Business (LB): Was LogiMAT Stuttgart where Bowe first demonstrated its new range of companies, brands and products?

Bas van der Velden (BvdV, pictured below): “Yes, it was where we really showed what we call the ‘Bowe ecosystem’, which is basically a combination of all the business units, and how that works together. ‘IQ’ is of course, as you know, the overlayer of everything concerning the controls part and also basically the brains of everything you have to move.”

LB: Bowe predominantly integrates its own products?

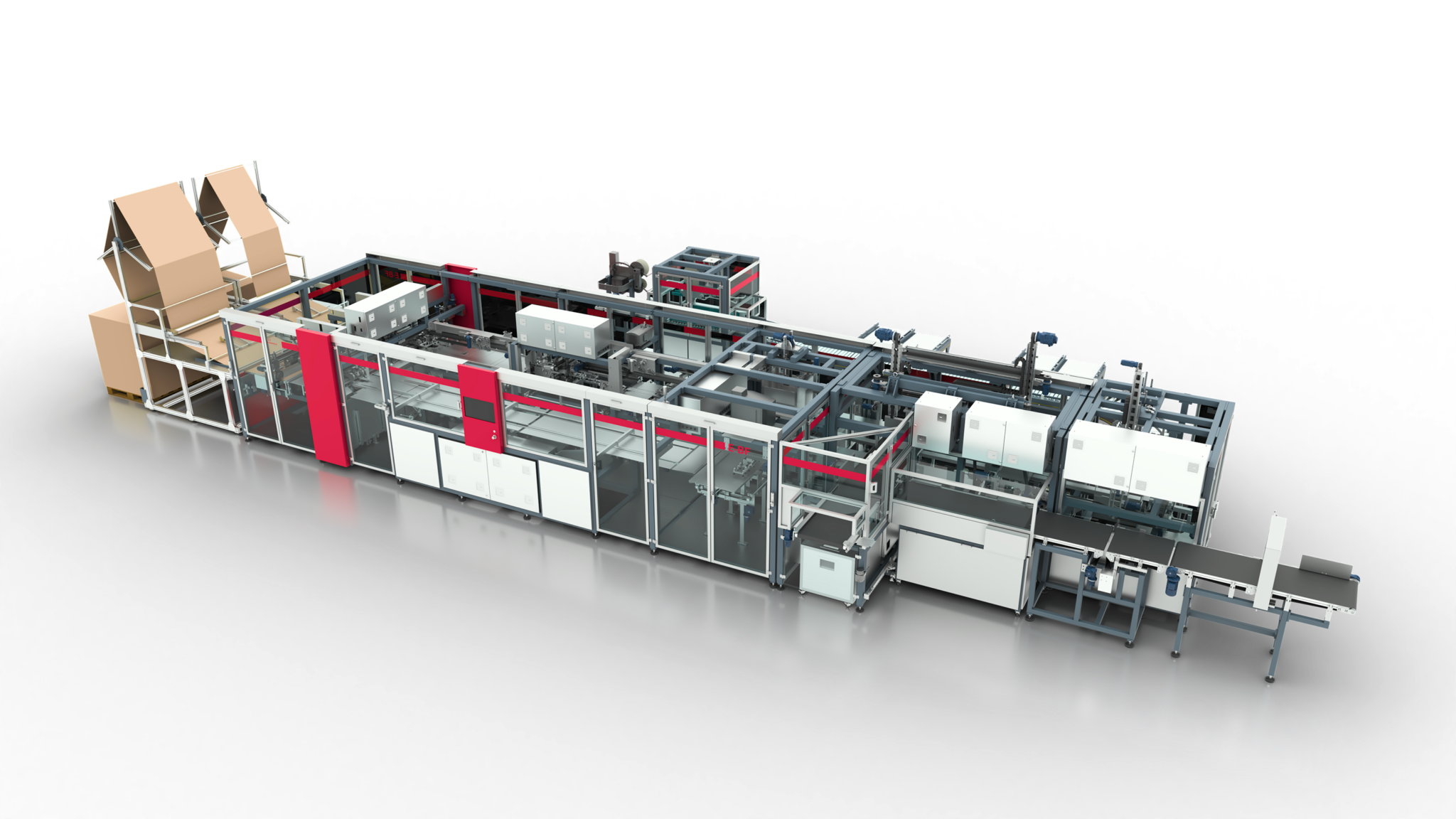

BvdV: “Yes, for 90% of all our projects we’re using our own portfolio. We see more and more that we can integrate many parts for our customers. So going, for example, from a letter sorter for DHL we can stack all those letters into a box. That box goes on to a conveyor belt. We have a robot arm picking those boxes with letters on the trolley and then an AMR takes that trolley away to a different part of the warehouse, for example. That is the Bowe ecosystem which we want to create.”

LB: How has the product range grown?

BvdV: “I feel it more than ever that things are really falling into place. We started, of course, with Intralogistics as the first part almost 10 years ago. We developed IQ from 2019 and Move is a little bit newer. But things are really falling into place now, and we see that also with the customers. We add value now with a larger perspective than before when it was only the sorting systems, for example.”

Bas van der Velden

LB: Within Bowe Move you offer an AMR range, including the Tugbot with its roll cage gripper?

BvdV: “Correct. The Tugbot can be everything. What is so special about it is that the gripper is very flexible and because it’s so small. We can navigate in small spaces, where maybe other suppliers are unable to. It can also go into reverse mode and park backwards. Those are definitely the unique selling points.”

LB: The Palletbot has forks?

BvdV: “Yeah, exactly, this is a fork-based AMR and the biggest of the products. You would sell this to customers with pallet handling operations.”

LB: In addition to other products?

BvdV: “Correct. If you look at AMRs, it’s all-round materials handling, basically going from A to B in a production or logistical process. In fast-moving consumer goods and food we see a lot of pallet movements and therefore the Palletbot is a good solution for that. In the warehouse, if you want to move things with an AMR you need flexibility. We have a product for all this.”

LB: Lastly, the Flexbot. This is the one with the picking arm. What are the specific applications for that?

BvdV: “The Flexbot is relatively new. If you have a multi-product warehouse and use different shipment containers or pallets then a Flexbot is a good choice because it offers flexibility for lower weights.”

Robust and Reliable

LB: Looking at Bowe IQ, this is the ‘yellow brand’. One solution that’s interesting here is the RFID gate.

BvdV: “Yes, you know that RFID was a real hype 10 years ago. I wouldn’t say it’s slowed down because it’s always been present, but people were talking less and less about it. We still see that people are using RFID, people want to use RFID, and our gates are perfect for it. If you have a full pallet, we move it around with the Palletbot and it needs to go from one part of the warehouse to the other or even goes to outbound. The RFID gate will scan everything automatically on the pallet and provide confirmation that everything is on it. Or maybe there is a product on it which shouldn’t be leaving that part of the warehouse or that its missing what was expected. That is all managed by us. The hardware is one part, so is alarming the operation and saying, ‘hey, we’re missing things’ or ‘wrong things are going to the wrong destination’ or to a wrong position in the warehouse.”

Most Efficient Solution

LB: Moving to your speciality area, Bas, – Bowe Intralogistics. This is kind of the legacy business, with the Optimus products. Is that the biggest of the three segments?

BvdV: “Well we have 4 sections if you include Bowe Systec, which is our postal sorting business. I cannot provide percentages, but Intralogistics is the largest business and became part of Bowe in 2016, with the Optimus acquisition. Of course, we’ve grown since then. We have a facility in Sweden and we have a production facility in Italy. Our turnover was about €7m when we entered the Bowe Group. Now our Dutch office is doing over €30 million alone.

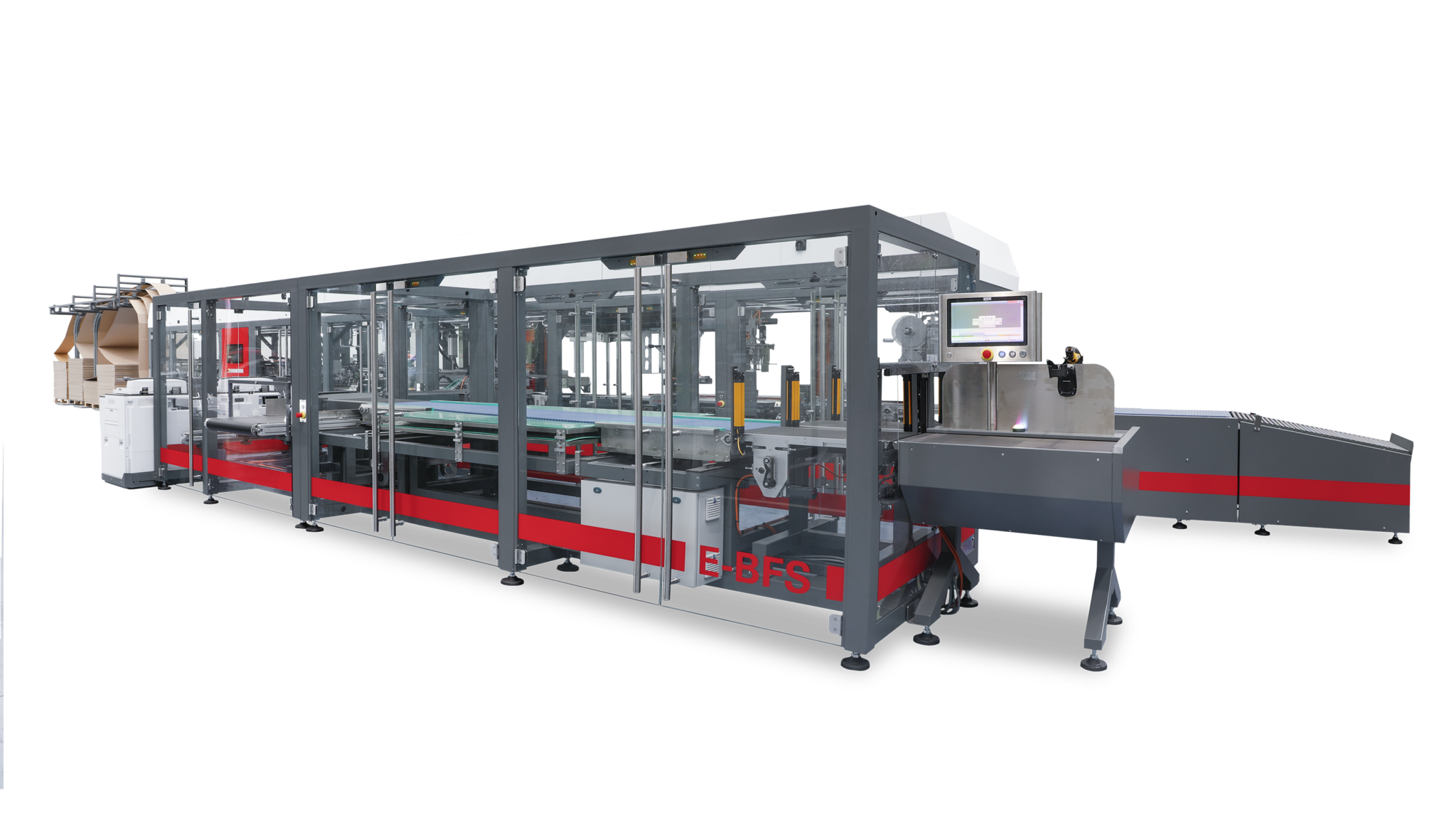

“We’re performing well and we see a lot of interest in our products. I think it’s good that we do our own integration. We do basically everything from A-Z, the one-stop-shop principle and we keep adding products. This is unique in the market. It’s all our own manufacturing, always with the same principles. It needs to be very robust and very reliable. This is one of the key reasons why customers choose us. Another big pointer is that we always want to go for the most efficient solution, with the most efficient products around it. If you look at the legacy business from Systec you see letter sorters and mailing machines. We were always the fastest, the only ones who were hitting the very high speeds.”

LB: The different sections of the business learn from each other?

BvdV: “We looked at that business model and we said, at Intralogistics, we can do roughly the same. We know that 95% of solutions that we deliver are sorting solutions and it’s always about input but combination with output is the most important thing. The shortest system will run reliably, has very high availability, low maintenance and service cost. If we are able to keep a constant high pace, then you have the perfect solution.

“This is where ‘Perfect Index’ or ‘Perfect Pitch’ comes in. If you look at the letter machines, they need to shoot in the envelopes at incredibly high pace and the way that they do that is by reducing the pitch between the letters as to as small as possible. What is the perfect induct, infeed line? We are trying to make them as efficient as possible by keeping the pitches and the gaps between parcels very small. We have very high outputs even on slower systems. In general, systems run one metre or 1.2 metres per second. If you look at the other suppliers and crossbelts, they need to run 2 metres or sometimes 2.6 metres per second. In most cases if you look at net output we are getting the same output as other suppliers.

“The market average for any sort of solution is to be around 75% or 80% operational. We are hitting above 90% and feeling great. We believe, well, we not only believe, we know it’s unique in the market. It’s a mechanical product, so you always need the operation to be good as well. We try to reduce the influence of the operator as much as possible. Let’s say it like this, David. If we step into a Formula One car, we are most likely not even able to start the car and when Verstappen goes in, or Hamilton, they are really getting the most output out of it. It works exactly the same with warehouse automation. You know you can place €100 million, €200 million or even a billion dollar’s worth of automation in a warehouse. But if the people around it are not aligned or don’t have a good day then the output will stall and not be not be what everybody expects. W we try to reduce that human factor by creating that consistency.”

Flexible and International

LB: Finally, to MOV.AI. This is the software for the AMRs. Is it an orchestration software for different types of AMRs, from different manufacturers? Is it a separate business from Bowe or a sister company?

BvdV: “Correct. Bowe has a majority share in MOV.AI. Like you say, it’s more of an orchestration software and the top layer of AMRs, doing the routing of the robots, which in essence is the most important part. You can have AMRs running around like crazy, but if you can utilise them and make it as efficient as possible, that’s good. I think the beauty about MOV.AI is that it doesn’t only work for our AMR infrastructure, but it also works for all AMRs, from different suppliers. So if you have multiple suppliers of AMR hardware in your warehouse then you can put the software of MOV.AI on top of it and everything connects with each other. This is also unique in the market.”

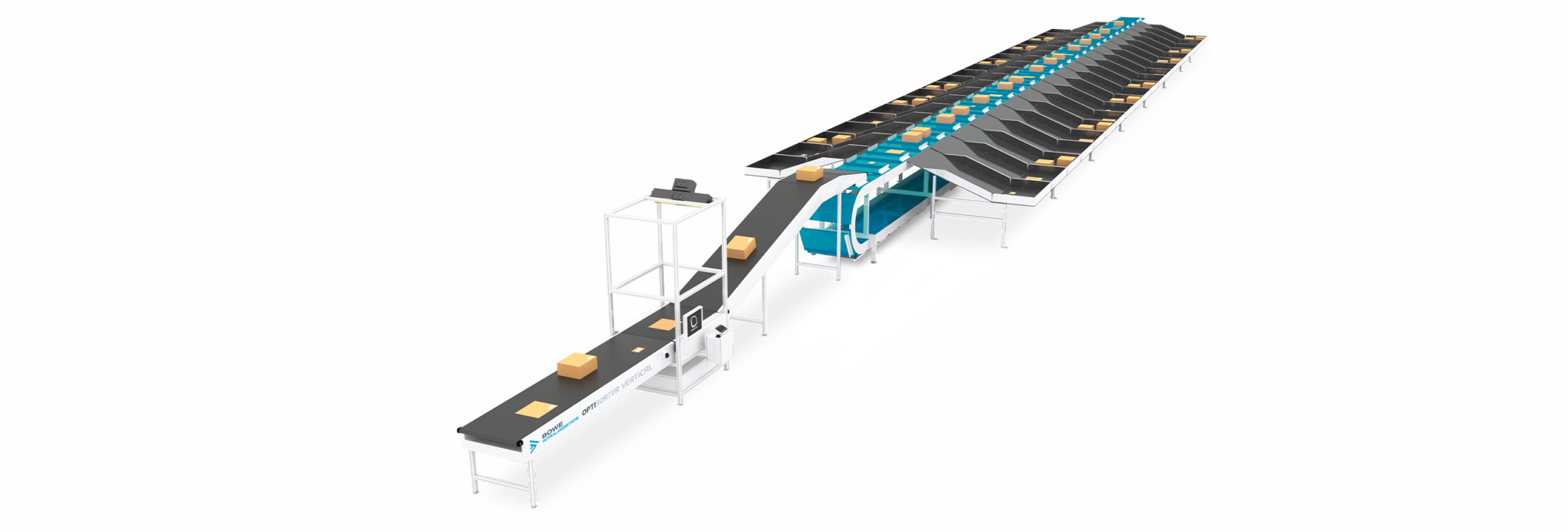

LB: Tell us a little bit about the Modular Vertical Sorter. Is this the new product for this year?

BvdV: “We introduced it last year in our customer days – a small exhibition where we invite customers to look at the ecosystem and show what we can do. We’re not only an IT company. We’re not only a mechanical sorting company. What makes these AMR so interesting for customers and why did we all jump on it? Because of the flexibility that they have, the very fast deployment time, but also if they need to change warehouse or change their operation, then their automation needs to evolve with them, to expand or in some cases even slimming it down a little bit. So we looked at traditional sorting and we said we need to do something similar, regarding visibility of the deployment rate and make it as easy as possible.

“The Modular Vertical Sorter was born to be very robust, very reliable, high capacity at lower speeds. But we needed to make it in a smaller package, which we can deliver very fast to help our customers, so they can extend if they need more capacity on site or even for example, if their peak period is over. It’s not even dismantling, just moving the sorter to a different place in the warehouse so that you get some operational work area back. It’s our standard vertical sorter, but we build it in modules. So you have a head and a tail module and a very large section of middle modules to extend the shoots with. We have the units in stock, so we can deliver. From the order to full integration on the warehouse floor in two to three months, which is unique in the market.

“What we usually see is that most customers are luckily for us on time with ordering their warehouse equipment, but it usually takes 6 to 9 months from order to implementation. We always have customers coming in the Spring and saying, do you still have availability, can we have a sorter for the for the peak season because we need to have that capacity. We unfortunately always needed to say no because it physically was not possible, but it is possible now. If customers come to us in June asking for extra peak capacity in November then that’s no problem. Use it, get extra capacity in their warehouse up to 10,000 pieces per hour. And if they don’t need it in their warehouse anymore after peak, they can basically pack it up. Takes a day. Put it in a different warehouse to gain extra capacity there or add some modules in between it as well to increase the sort capacity.”

LB: You have been future-proofing your portfolio.

BvdV: “We can do any anything from 500 pieces per hour up until 20,000 pieces per hour. That’s a very wide range. In every range of that sorting capacity we have very competitive portfolio. We are not just integrating. We control everything from a quality aspect from the purchasing part up until the integration and then the aftersales service.”

similar news

Engineering Firm to Increase Output With New Automated System