Eurosort recently appointed Rens Gehling as its new Commercial Director, with a brief to chart and deliver an even brighter future for the Netherlands-based sorter supplier. Paul Hamblin meets him.

In the increasingly dizzying world of logistics integration and automation, it pays to be a specialist. If you’re known – and more importantly, admired and respected – for a core offering, it gives you two tasty bites of the cherry; as a go-to choice OEM supplier for the big integrator players, as well as a trusted resource for direct customer sales.

Fact: the Dutch are good at sorting. Many of the big players in the field are Netherlands-founded and based and they continue to lead the way in innovation and efficiency in a sector which, thanks to ecommerce, has enjoyed a strong growth path over the past decade and more.

A fine example of all of the above is Eurosort, which also operates under the Distrisort brand. Tell us the difference between the two, I ask Rens Gehling, the new Commercial Director, appointed in a key leadership role to the Amsterdam-based company in January this year.

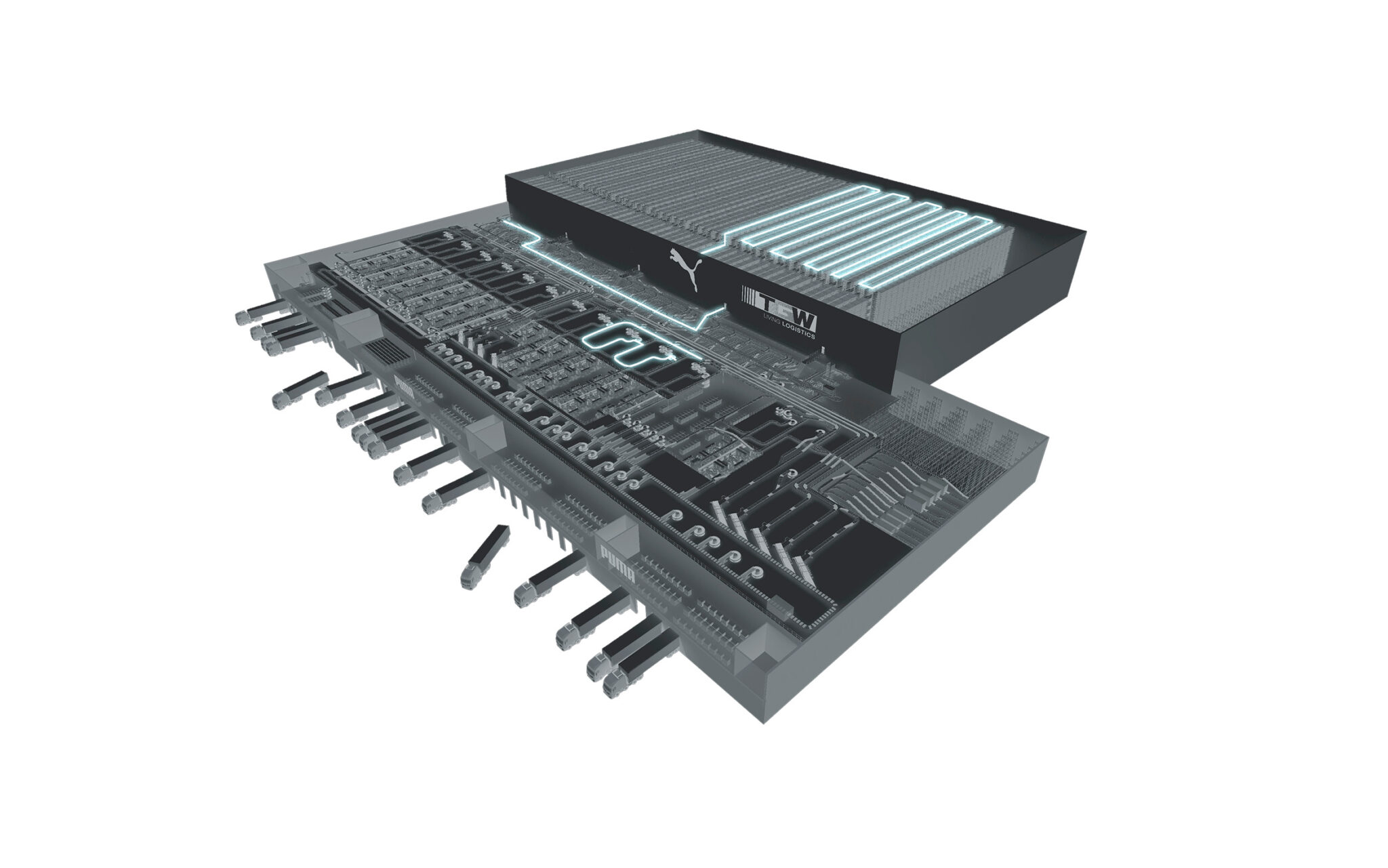

“Eurosort and Distrisort are two brands, but one company, same location, same people,” he explains. “Eurosort is a sorter OEM, developing, building and selling high-quality sorters, usually to integrators. Technically, when we deliver to integrators, we control the system with our PLC/software. However, in general terms, the word ‘software’ is considered to refer to the WCS, which is always integrator-based. Projects are flexible – they can be turnkey, they can incorporate controls or they can be mechanical only, using separate controls and software preferred by the customer. The point is that the customer has control and we provide what they ask for.

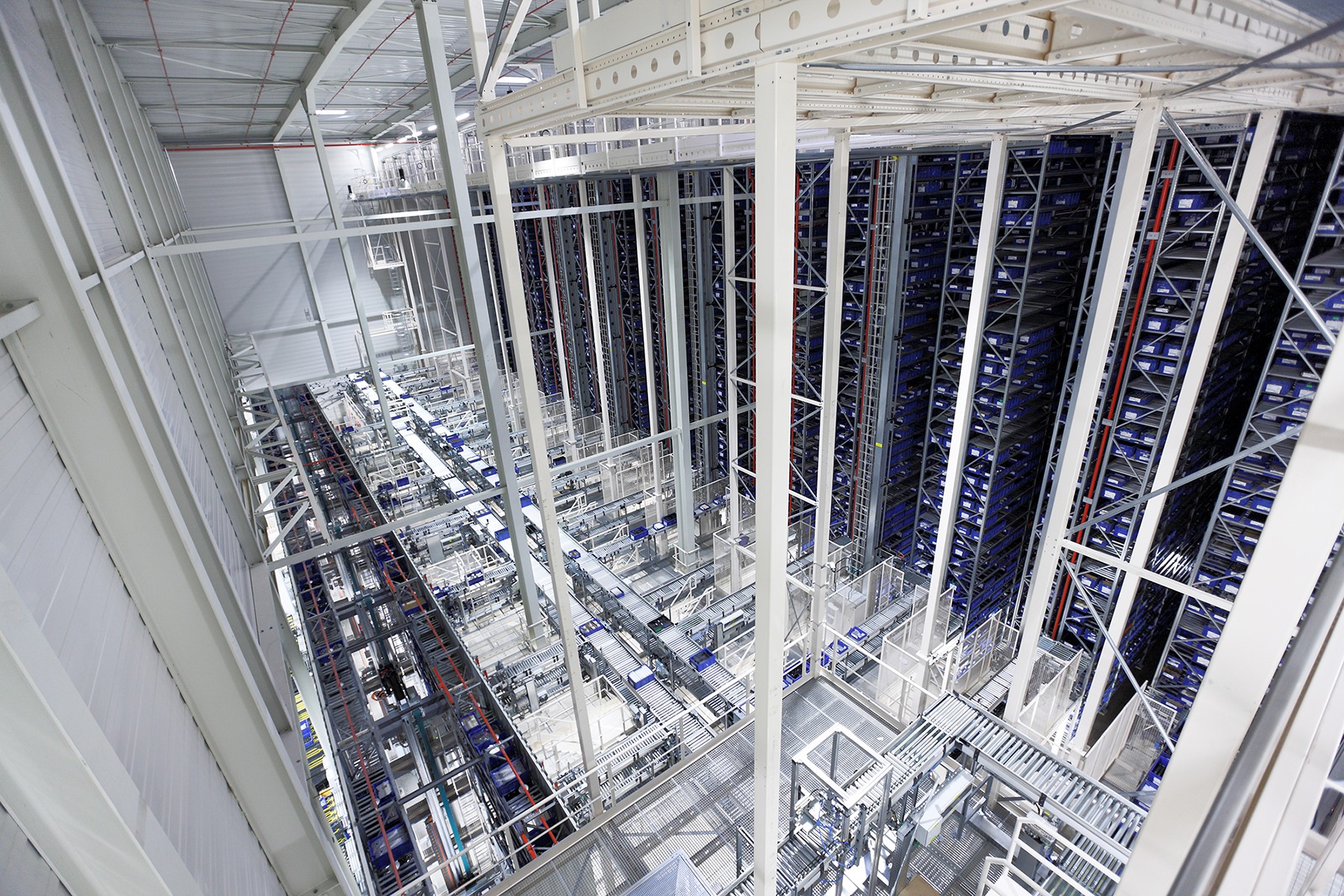

“Distrisort sells sorters direct to end customers. Usually, these are turnkey solutions, mainly in the fashion, consumer goods, and postal spaces. Our speciality is in providing our customers with solutions for high-speed, high-capacity lightweight products with examples of systems sold capable of handling 100,000 items per hour, which have given us a dominant market position.”

The company grew exponentially during the ecommerce boom part-driven by the pandemic, but Eurosort is certainly not resting on its laurels. Gehling is at Eurosort to scale the company still further. “I’m here to establish how we scale, how we make our success repeatable and predictable, to push on our business development and market intelligence to pinpoint where we see ourselves in 10 years time,” he reflects.

It’s a task for which Gehling is well qualified. Steeped in sortation technology after a successful career at Bowe Intralogistics, he holds two master’s degrees in Mechanical Engineering and Physics and brings expertise in ecommerce, as well as significant legal, organisational development, and R&D experience.

Future Customer Needs

He knows the company is already successful at finding and retaining a loyal customer base – one client alone has bought as many as 90 sorters – and sees the challenge to be about identifying future customer needs and being ready to meet them quickly and cost-effectively. “For instance, we are making great strides in combining traditional retail sorting processes with ecommerce sorting processes, and greatly increasing the potential number of exits,” he reveals.

Are ecommerce and retail not the same these days, I query? “Ecommerce generally comprises batch picking of a low number of SKUs per order, whereas retail sorting may comprise dozens of SKUs per single order,” he explains.

Favoured solutions are often those which enable the customer to make maximum economic and practical use of precious space. Eurosort examples include the Chute Pitch Reducer, a door sited to stop a product from sliding down the chute in its track. The benefit is the opportunity to increase the number of exits in the sorter loop.

A further exciting innovation due to come on stream later this year is the Prote-E (a Vertical Exit Multiplier Module). It massively increases the opportunity to boost the number of exits for products of many sizes and weights, allied to an automated put wall system that exploits space to increase storage and separation options. “We specialize in customised, engineered exits, whatever is relevant and appropriate for the customer’s operations,” he comments.

Eurosort’s not-so secret weapon is its patented split tray sorter (also known as a Bombay or flat sorter), a simple, but ingenious idea to increase capacities at a stroke. “Single loop, cross tray, push, cross – whatever sorter type you need, just use a dual split and you have twice the capacity at the same cost. You just can’t beat it,” he smiles. “Everything you would want to do on a loop sorting operation, deploy a split tray, because it will give you simply the best ROI ever.”

Sorter Types Defined

To new customers not versed in the language of sortation, the terminology can be confusing. He provides an easy summary of each sorter type.

“With split tray sorters, the product drops downwards when it is selected for a tote or other destination. Most of the time that’s fine, but of course not every SKU or package can be allowed to drop, usually due to size, weight or fragility restrictions. So, anything non-breakable we can’t allow to drop, we then move to push tray sorters, where we push out the product to a destination on the same level.

“A crossbelt sorter is designed to accept items of greater weight and size and offers tremendous speeds and throughputs. Crossbelt sorters are very effective for fast movement of bulkier items but the downside is that they are more expensive, can’t handle small items well and add maintenance complexity. That’s where our cross tray sorter comes into its own, which I’d describe as a mini crossbelt. It’s cheap to buy and run, designed for small to mid-sized, non-conveyable items that are enclosed in a tray. Because this is our specialty, we wanted to offer this option to our customers. In fact, it can often be a much better fit than many crossbelt sorters.”

One future opportunity for Eurosort is in supplying space-efficient secondary sorters focused on small items to supplement existing larger solutions in a DC. Separately, the company is starting to see projects in which customers with lower capacity requirements are looking to combine inbound, outbound, consolidation and returns into a cost-effective single, closed sortation system.

similar news