Schlüter-Systems KG, a the global supplier of system solutions for tile and natural stone installation, needed seamless, fast, scalable logistics across its 35,000 m² facility. From its headquarters in Iserlohn, Germany, the company supplies wholesalers, construction sites, and tile warehouses around the world. As the former craftsman business has grown into a globally operating enterprise, the demands on its logistics and warehouse management have increased significantly.

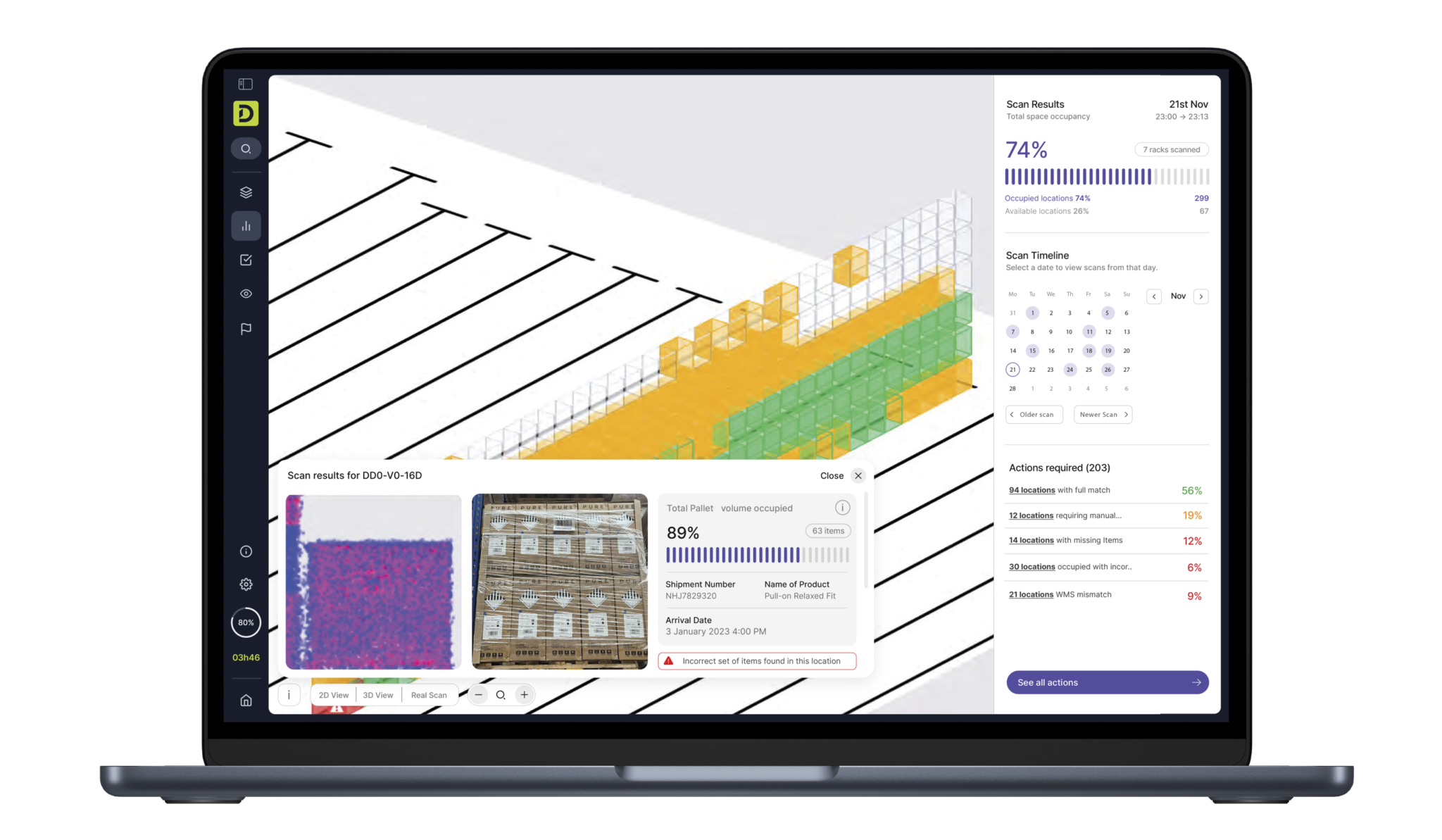

In response, Schlüter-Systems has accelerated the digitalization of its warehouse operations across the group and built a new central warehouse at its headquarters. At the heart of this transformation is the LFS warehouse management system from EPG (Ehrhardt Partner Group), which ensures the coordination of all logistics processes. The result: noticeably improved efficiency, maximum flexibility, and a significantly lower error rate.

Schlüter-Systems offers a wide range of products, including various types of Schlüter profiles, electric and hydronic radiant heating systems, drainage solutions, and much more. With a portfolio of over 12,000 items, the company has successfully expanded into new markets and continuously enhanced its logistics capabilities. At its new warehouse in Iserlohn, Schlüter-Systems stocks approximately 12,000 products across 35,000 square meters and two levels.

From Driverless Transport Systems to Overhead Monorails

Fast shipping requires fast logistics — and a high-performance warehouse management system. As the previous WMS and ERP systems could no longer meet the demands of the new warehouse, Schlüter-Systems decided it was time for a change. After a thorough and lengthy selection process, the company chose the LFS warehouse management system.

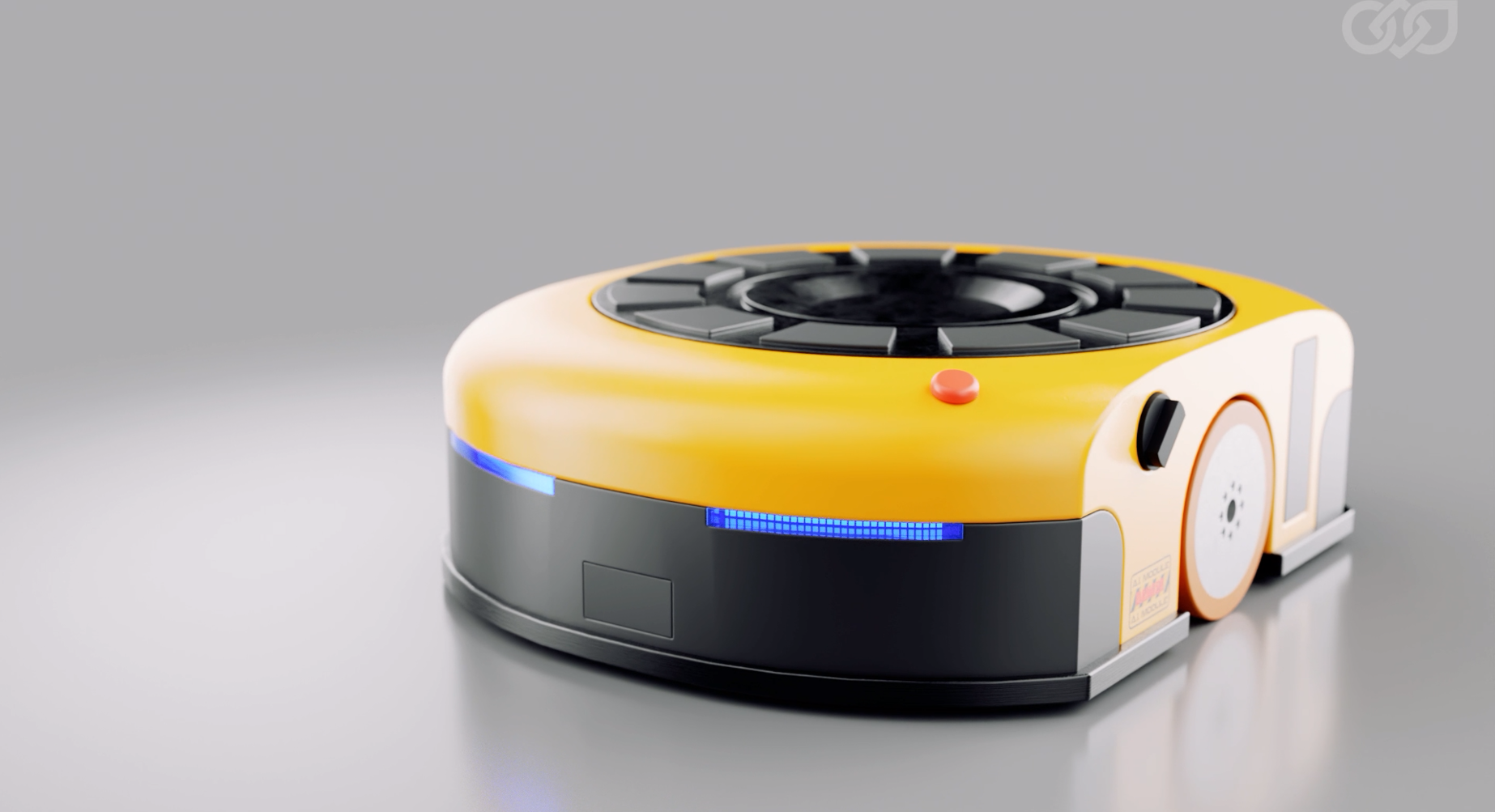

“In our new central warehouse, we’ve implemented a very high level of automation — with three automated high-bay storage systems, a driverless transport system, an automated small-parts warehouse, and a self-driving overhead monorail,” says Florian Schmidt, Head of Logistics at Schlüter-Systems. “The main challenge was getting the WMS to seamlessly connect all these systems and coordinate the material flow without disruption.”

By implementing LFS, Schlüter-Systems aimed to enhance picking and packing strategies, optimize material flow, and make processes more efficient and transparent. Thanks to close collaboration with the Schlüter-Systems project team, the supply chain specialists at EPG successfully implemented LFS at the site and coordinated all automation solutions within just a few months. “For the suspended monorail system, which can transport various items with a total weight of up to 1.3 tons, there was previously no existing interface,” explains EPG Project Manager Markus Pauly. “We developed a custom connection from the ground up to ensure seamless integration into the system.”

Efficient, Ergonomic, Error-Free

The modular LFS system helps Schlüter-Systems design automation elements at different communication levels and interfaces with shipping service providers in a sustainable and efficient way. “One of the challenges was coordinating the wide variety and complexity of components in day-to-day operations,” says Schmidt.

In addition to the driverless transport system (FTS), the company also uses the cloud-based International Shipping System (ISS), which offers user-friendly features like Track & Trace, interfaces with over 250 shipping carriers, and fully automated shipping label printing.

similar news