Transparency of the global supply chain is becoming the weapon of choice for smart logistics operations, as Peter MacLeod discovers in a conversation with Setlog’s Ralf Düster.

As the supply chain world hurtles toward a more interconnected and complex future, it is clear that end-to-end visibility is a necessity. Ralf Düster (pictured below), Managing Director of Setlog GmbH, advocates that managing global supply chains effectively means seeing the whole picture, from raw material readiness to last-mile delivery. And with the company’s digital platform, OSCA Global Logistics, Setlog is equipping its customers with the tools to navigate an increasingly unpredictable logistics landscape.

In a recent conversation following Setlog’s appearance at LogiMAT, Düster broke down how Setlog’s approach aligns with the top 10 supply chain management trends of 2025, as outlined in its latest industry report. From AI to cybersecurity, labour shortages to sustainability, he explained how Setlog is helping customers prepare for tomorrow’s challenges today.

End-to-End Visibility

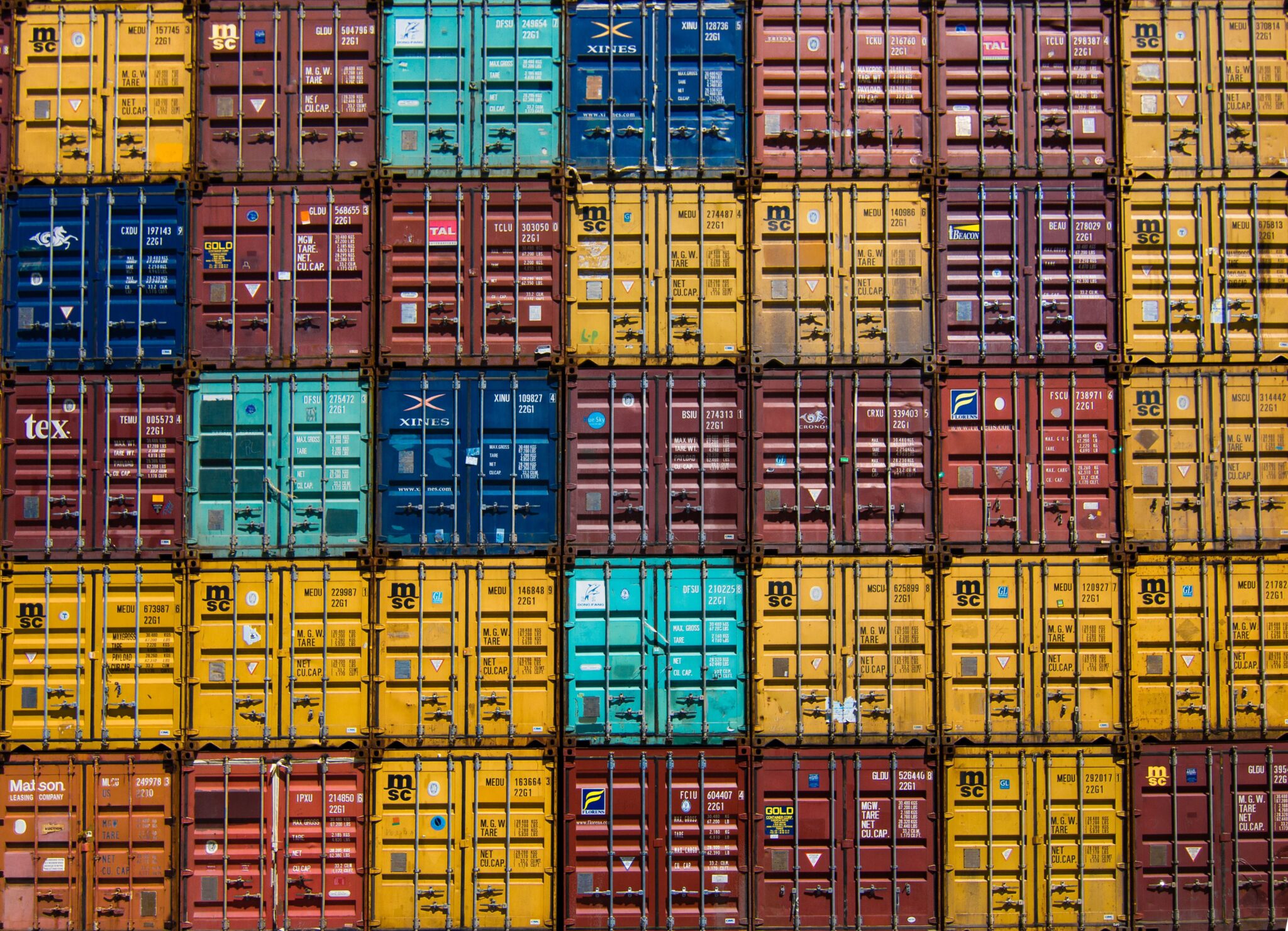

At the core of Setlog’s value proposition is deep visibility across the entire supply chain. “Today, it’s not enough to know where a container is,” says Düster. “You need to know when production starts, what the quality control results are, and if your materials are available in time. That’s the level of granularity we offer.”

Setlog’s OSCA platform allows businesses to gain SKU-level visibility very early in the development cycle, all the way up to the packing stage. Here, an electronic packing list generated at the factory enables accurate, real-time insights long before goods are shipped. This means DCs can prioritise container unloading, prepare resources more effectively, and ultimately serve their customers faster and with greater accuracy.

Ralf Duester, Setlog

Responding to Disruption

In a world rocked by geopolitical tension, climate events, and port congestion, supply chain disruptions are inevitable. Düster isn’t in the business of predicting wars or volcanic eruptions – “I’m not a Trump advisor or a volcano specialist,” he jokes – but he is in the business of building resilience through data. “When production delays happen, our system alerts you early,” he explains. “You can then make decisions like adapting the production, upgrading from sea freight to air freight or arranging two-driver express trucks to reduce delays. You don’t wait until the goods are on the water, you act at the production stage.”

By integrating supplier, lab, and logistics data into one collaborative platform, OSCA empowers businesses to adapt quickly and communicate changes to stakeholders, from internal planners to end customers.

Sustainability & Carbon Reporting

One of the most critical priorities for modern supply chains is reducing carbon emissions. Setlog’s platform offers detailed CO₂ tracking not just by shipment, but by SKU. This enables brands to analyse the environmental impact of individual products or ranges, helping them make greener logistics choices and meet evolving reporting standards.

“Companies can use this information to optimise transport modes, maybe to send mission-critical parts by air, and everything else by sea,” says Düster. “We give them the data to reduce emissions and maintain service levels.” With cyberattacks on the rise, Düster emphasises that Setlog invests heavily in security. “We’re handling sensitive data such as pricing, designs, product images, so we’ve built robust systems with strict access controls,” he says.

The platform is designed with role-based permissions, ensuring that only authorised users can view or modify specific data. Setlog also works with certified European and American data processing partners to maintain the highest security standards. As the supply chain becomes more digital and connected, this kind of protection is essential.

Labour Shortages

Another looming challenge is the growing scarcity of skilled logistics personnel, particularly in customs, warehouse operations, and intralogistics. Setlog is tackling this by supporting the shift toward Fourth-Party Logistics (4PL) models, where a single provider manages and orchestrates the full logistics operation on behalf of the customer.

“Companies want to focus on their core business: making products and serving customers,” says Düster. “They don’t want to worry about customs clearance or warehouse management. That’s where 4PL comes in.” Setlog is currently supporting the development of such a model for its customer Rhenus, a major logistics provider. The goal is full orchestration of everything from carrier selection to distribution centre operations, allowing businesses to remain agile even with fewer in-house logistics professionals.

AI Where it Matters

While many companies claim to use AI, few apply it where it counts. At Setlog, artificial intelligence is being embedded directly into operational workflows. From automated document processing to AI chatbots that answer real-time supply chain questions, OSCA is learning from every user interaction.

“We’re using AI to read laboratory QC reports and automatically trigger workflows,” explains Düster. “We’re also launching chatbot support so users can ask questions like ‘Is this order on the vessel?’ and get instant, accurate answers.” This reduces the need for manual intervention and allows merchandisers and logistics coordinators to focus on exception handling, rather than chasing routine updates.

While Setlog is headquartered in Germany, its footprint and its competitive mindset is international. “The US market is ahead in some areas, especially in adopting digital-first logistics platforms,” says Düster. “But we’re learning fast, and building solutions for both European and American clients.”

He points to the company’s involvement in the Open Logistics Foundation, and its participation in recent hackathons focused on digital air waybills and delivery documents. These innovations are helping reduce manual work and increase speed, which are two major drivers of supply chain efficiency.

The supply chain of 2025 demands more than fragmented software and Excel spreadsheets. It requires an integrated, collaborative ecosystem, one that gives all stakeholders the data they need to act quickly and intelligently. The OSCA platform offers that ecosystem, combining real-time visibility, intelligent automation, and robust security in a single solution. “If you want to be ready for the unknowns, whatever form they take, you need transparency and collaboration,” says Düster.

In an industry defined by complexity and change, that kind of clarity may be the most valuable cargo of all.

similar news